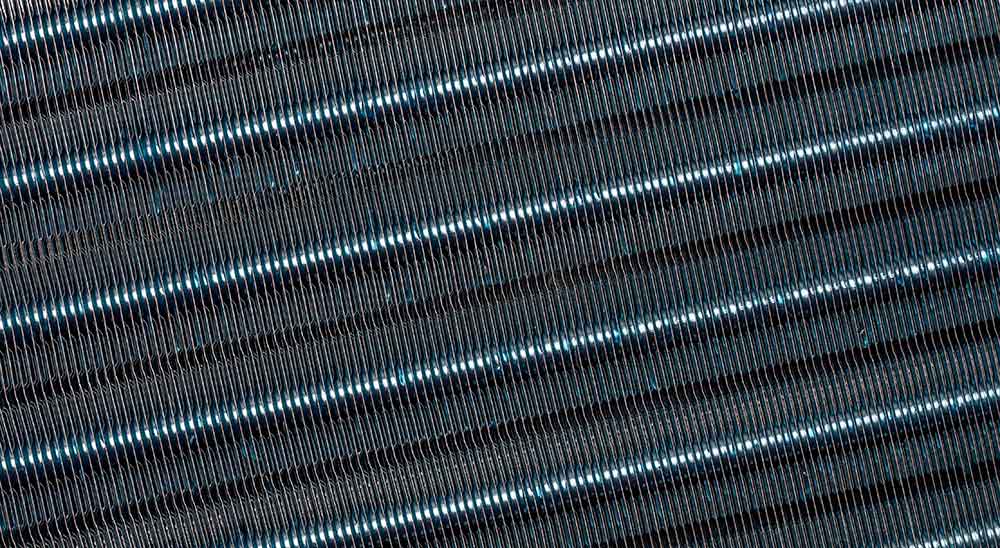

JAPAN: Daikin plans to produce air conditioner heat exchangers from recycled aluminum after improving its horizontal recycling method.

Air conditioner heat exchangers traditionally use high-purity aluminum, which is easy to process, but recycled aluminum fins from used heat exchangers contain copper and impurities, and were previously only used for other purposes, such as car engine parts. Once the quality of aluminum is degraded, it is difficult to restore it to its original state.

In collaboration with recycling company Nippon Magnetic Dressing and global aluminum company UACJ, Daikin is exploring a method of resource circulation through horizontal recycling, in which the use remains the same before and after recycling.

By improving the accuracy of sorting aluminum and copper and the ease of aluminum extrusion, the project is said to have successfully manufactured heat exchangers using recycled aluminum fins on the production line.

It is said that CO2 emissions from the production of recycled aluminum can be reduced by 97% compared to its production from virgin metal.

Recycler Nippon Magnetic Dressing developed advanced technology for sorting aluminum and copper and succeeded in reducing the copper content from an initial level of about 3% to less than 0.1%, while UACJ developed an aluminum material with improved pressure formability, which is a problem when copper and other impurities are present. Daikin used this aluminum material to perform fin pressing and heat exchanger production.

Daikin says it will work on mass production of heat exchangers made from recycled aluminum, focusing on used heat exchangers that are disposed of as industrial waste at Daikin factories and after-sales services.